Welcome to Realsense

We are team of people focused of production optimisation and energy saving

Production Efficiency

Collecting manufacturig data to monitor and optimize your production OEE factor

About

Find Out More About Us

Meet Our Expert Team in Industrial Processes, Automation, and Lean Manufacturing

Our team consists of highly skilled professionals with vast experience in industrial processes, bringing innovative solutions to complex challenges. We excel in automation, leveraging cutting-edge technologies to enhance productivity and precision.

-

Expertise

Our expertise in lean manufacturing enables us to streamline operations, reducing waste and maximizing efficiency.

-

Experience

With a proven track record, we have successfully implemented numerous projects across various industries.

Our commitment to continuous improvement drives us to stay ahead of industry trends and advancements. Dedicated to delivering excellence, our team is your trusted partner for optimizing industrial performance.

Services

Check Our Services

Condition Monitoring

Vibration monitoring of machines provides early detection of mechanical issues, preventing potential failures and costly downtime. It also helps optimize maintenance schedules and improve overall equipment efficiency.

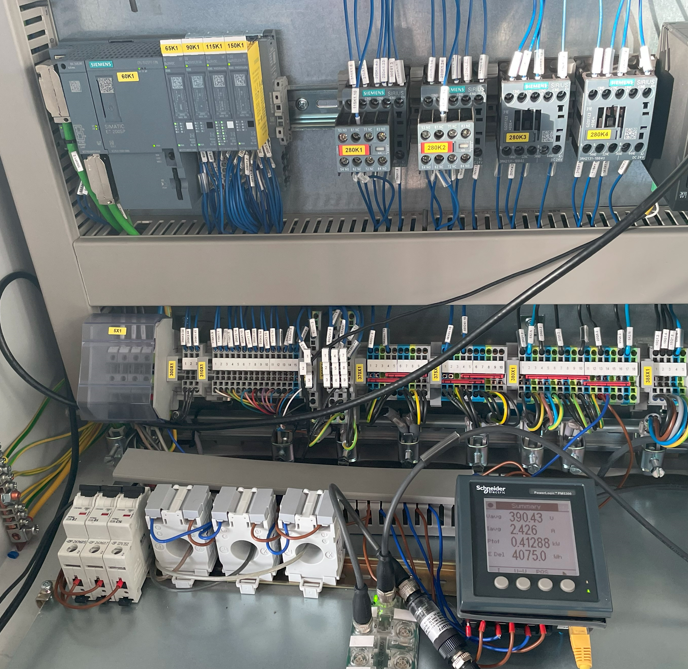

Media and Energy Monitoring

Media and energy monitoring allows for real-time tracking of resource consumption, leading to more efficient usage and cost savings. It also aids in identifying inefficiencies and promoting sustainable practices within an organization.

OEE Factor Measurment adn Monitoring

OEE factor measurement and monitoring provide insights into the efficiency, performance, and quality of manufacturing processes, helping to identify areas for improvement. This enables companies to maximize productivity, reduce downtime, and increase overall operational effectiveness.

Assets Tracking

Assets tracking in an industrial plant enables real-time visibility of equipment and inventory, enhancing operational efficiency and reducing losses. It also improves maintenance management and utilization rates, ensuring that assets are optimally deployed and maintained.

RFID Tool Passport

An rfid tool passport provides a comprehensive record of tool usage and maintenance, ensuring accurate tracking and better management of equipment lifespan. This helps in reducing downtime, optimizing tool performance, and ensuring timely maintenance and replacements in an industrial plant.

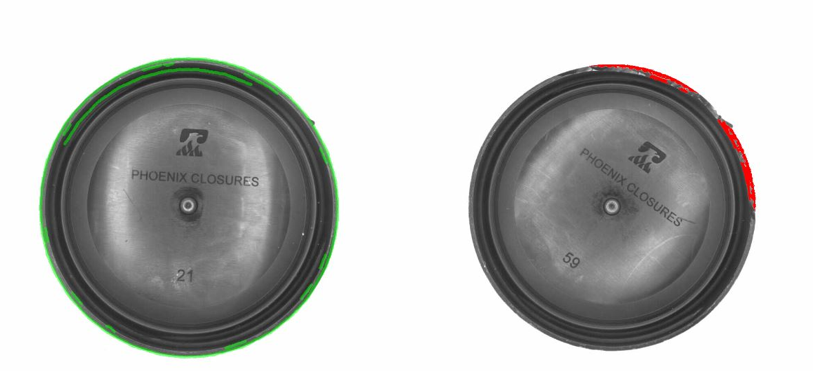

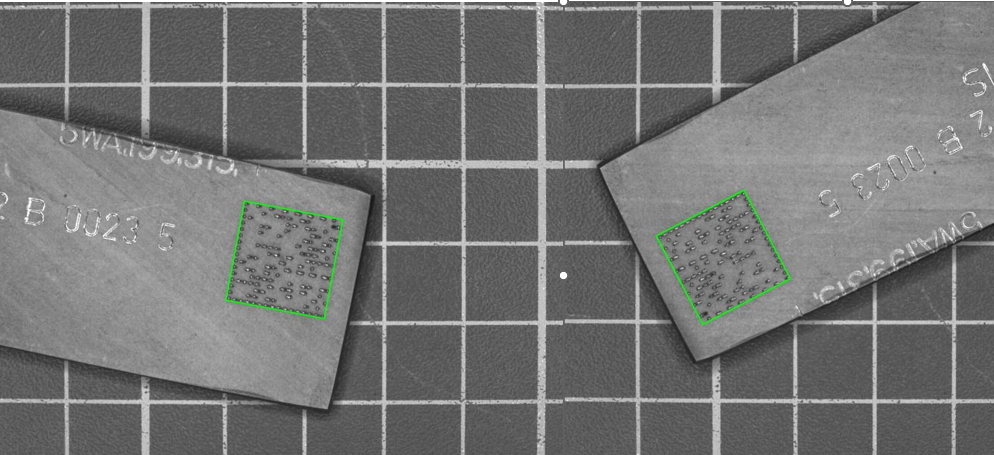

Machine Vision Systems

Machine vision in an industrial plant enhances quality control by providing automated, precise, and consistent inspection of products. It also increases production efficiency by enabling real-time detection of defects and reducing reliance on manual inspections.

Portfolio

Check Our Portfolio

- All

- Assets Traceability

- Condition Monitoring

- Media and Energy Monitoring

- Machine Vision

RFID

Tracking of the milkruns with RFID tags

Intralogistics RFID

Tracking of the boxes in the factory

RFID UHF Gates

Automatic UHF gates in Intralogistics

Codition Monitoring

Continuous robot vibration monitoring

Electrical energy consumption

Continuous electrical consumption monitoring, on-premise or cloud based

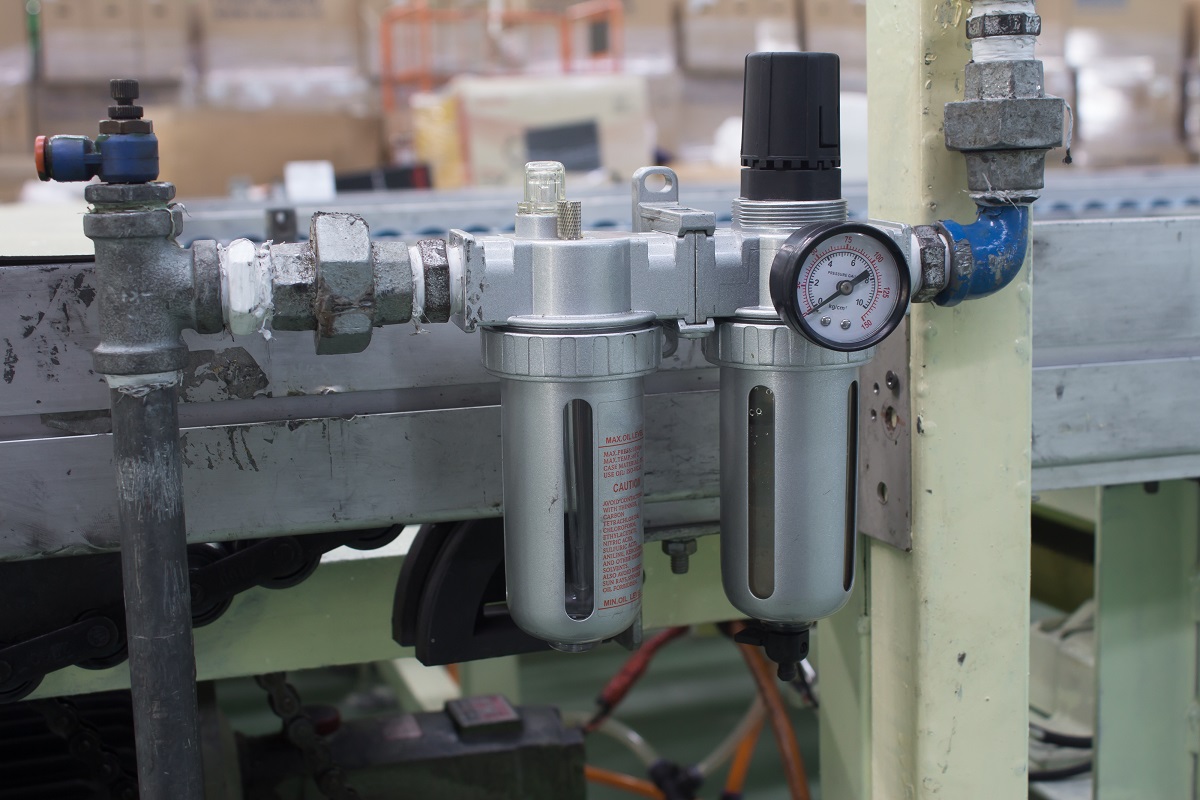

Compressed Air Consumption

Continuous compressed air monitoring

Electrical energy consumption

Broad variety of interfaces: ModBus TCP, OPC UA, REST API, Impulse Outputs

Wind Turbines

Continuous vibration and temparature monitoring of the wind turbine drives and the bearings

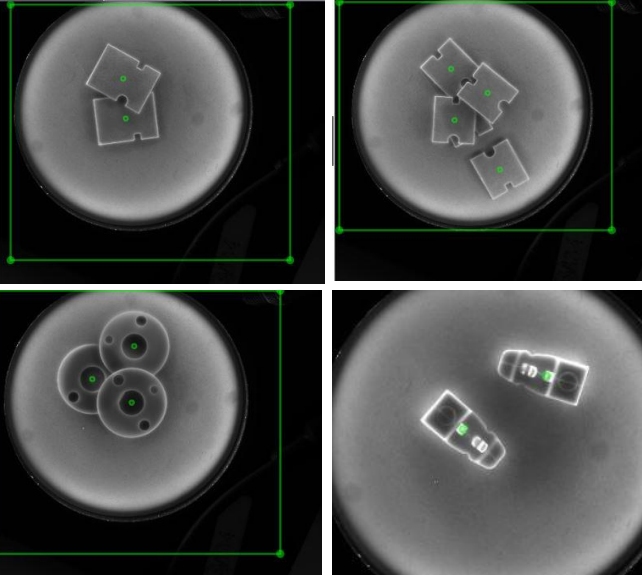

Object detection

Object detection and robot positioning

Quality Control

Final product quality control. Shape, color or completness check.

Code Reading

Parts Visual Identyfication

Pumps

Continuous condition monitoring of pumps, couplers and the tranmissions

Contact

Need Help? Contact Us

Address

ul. Stanisławowska 47, 54-611 Wrocław

Call Us

+48 505 421 617

Email Us

office@therealsense.com